Back

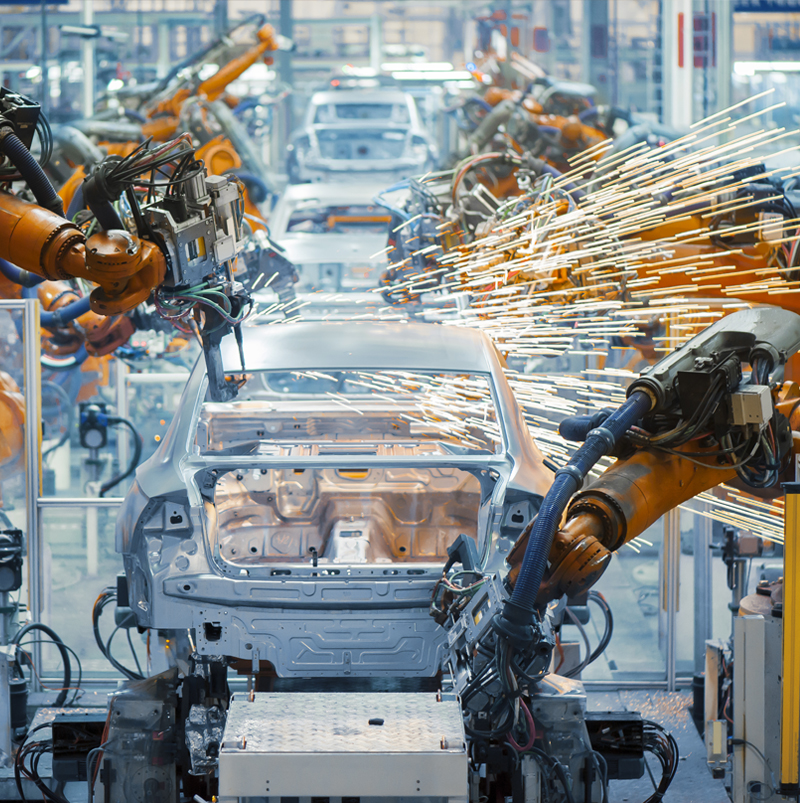

Impact of Mega Trends – Manufacturing industries

- By Elite CIO

Feb 18, 2019

Feb 18, 2019 3

3

Dear friends, Technology is changing day in and out and almost from past years’ our IT industries are talking about the technologies like IOT, Manufacturing 4.0, IIOT.

Dear friends, Technology is changing day in and out and almost from past years’ our IT industries are talking about the technologies like IOT, Manufacturing 4.0, IIOT.

Dear friends, Technology is changing day in and out and almost from past years’ our IT industries are talking about the technologies like IOT, Manufacturing 4.0, IIOT, additive manufacturing, AR/VR, AI, ML/DL, Block chain & GPS enabled application etc.These technologies are helpful to the various business verticals and some of these technology are the trend setting in manufacturing Industry.

In process of selection of trending technology, the CIO has to find answers of these questions:

1. What technologies can help the Industry to Improve productivity and how?

2. What is the impact of automated processes within the dimensions of Value Chain, Product and Ecosystem?

Many of our friends have a thought, is this is the right time for the digital transformation or we have to wait and watch for a case study. The mentioned below facts assure us that the right time has come for the adoption of trending technology as per our business requirements.

• Computing power is – close to human brain

• Good Internet band width availability at a point

• Miniaturization: sensors everywhere

Digital technologies have grown exponentially, but they have now reached at a point where they can transform the operations. Friends the 4th industrial revolution is blurring the lines between the physical, digital and biological spheres of production.

Friend’s combination of modern digital technologies leads to the fast development off our new industrial capabilities. The key Capabilities and related technologies are as under:

• Connectivity and computing power

• Analytics and intelligence

• Human Machine interface

• Digital- Physical transformation

Connectivity and computing power – Enables us to generate Data from anything

Digitization requires computing power and networking, as with the exponential increase in the number of IoT-enabled devices, machines, and consumer gadgets, the number of data to be evaluated is growing. Data acquisition with unfiltered transfer to a cloud is pointless and very expensive. In an Industrial 4.0 environment, reactions to sensor and actuator feedback must more often than not occur virtually in real time. Here Intelligent Edge Computing with compact, robust and increasingly powerful embedded boards and modules as well as industrial PCs, ensures fast, reliable and uninterrupted data processing close to the point of origin. The cloud assumes different tasks. In this area, the trend will continue – tied to the development towards more processor power and extended memory size: more and more cloud tasks such as Edge Analytics will be shifted to Intelligent Edge Computers.

Friends, I would like to keep this as an series of my write-ups on trending technologies and its usage in the manufacturing environment … I will cover the rest of the points in second right up.

Author – Mr. L. K. Tripathy, CGM-IT, Rockman Industries